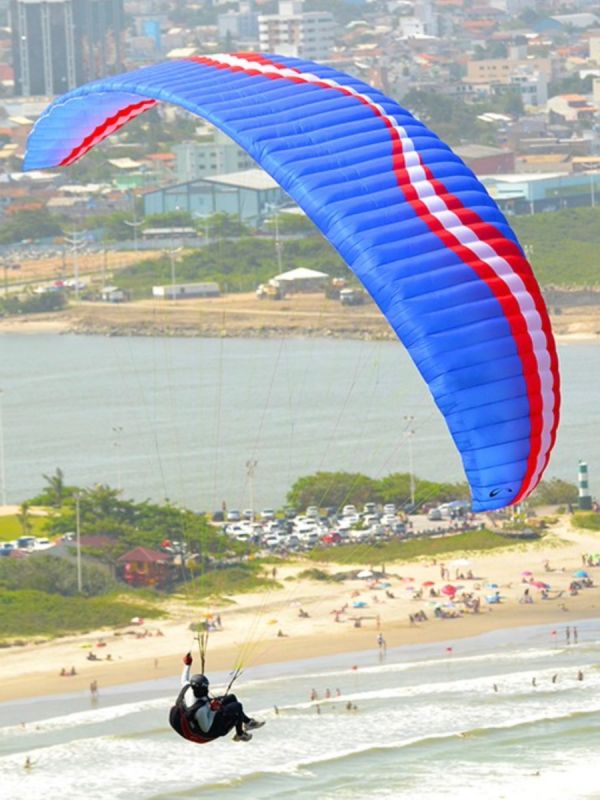

As successor to the first version, on the all new designed ATMUS 2 were applied numerous performance-enhancing innovative technologies and intelligent detail solutions.

To create less impact on the environment, a big part of the ATMUS 2 is made of undyed fabric, as all of our wings produced from 2017 on.

The fabric used in profiles, diagonal tabs and diagonal profiles, representing 40% of overall consumption, don't suffer dyeing process anymore what means a reduction of water consumption in the same scale.

The ATMUS 2 consists of 47 cells and has internal crossed diagonals applied at the profiles to distribute the weight uniformly. This maintains the canopy very shapely and cleans and reduces the induced drag.

The ATMUS 2 was designed at the new software. Its enhanced design and profile are the result of our continuous development and refinement process in terms of performance paired with stability. The improved features of this project permit a large speed range and excellent stability.

Flight characteristics

Its higher aspect ratio allows a more precise piloting both to active pilots who like to use the body, as well as to passive pilots who prefer to act using the brakes. This characteristic allows a great performance in weak and strong thermals, while stability is maintained.

| Long and tolerating brake length; | |

| Excellent and precise handling; | |

| High internal pressure; | |

| Stability in full speed; | |

| Light reactions in extreme conditions; | |

| Excellent take off characteristics, even in nil wind; | |

| Comfortable piloting; | |

| Good behaviour in thermals. |

Remarkable

| Comfort | Easy handlíng | X-Battens | |||

| Lighter | Long life | 3D Shaping | |||

| Performance | Pressure Booster Profiles - Shark mouth | Mini Ribs | |||

| Hybrid riser and line system | Risers for big ears | Ease of climbing in thermals | |||

| Ecologic | Higher Project Aspect Ratio |

Technology

|

Pressure Booster Profiles - Shark mouth |  |

3 Riser-system |

|

X-Battens |  |

Laser cut |

|

Hybrid Materials |  |

Load Distribution Tapes |

|

3D - Shaping |  |

Mini Ribs |

|

Flexible Battens |  |

Higher projected A/R |

|

Bow Tec |

| Brand | Sol | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specs |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Material | Since 1991 SOL has been producing and following the evolution of materials and products. Our experience makes us choose the materials carefully, thus guaranteeing a good stability and a high safety level. All SOL Paragliders are manufactured in our own plant, certified by DHV.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Package Includes |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||